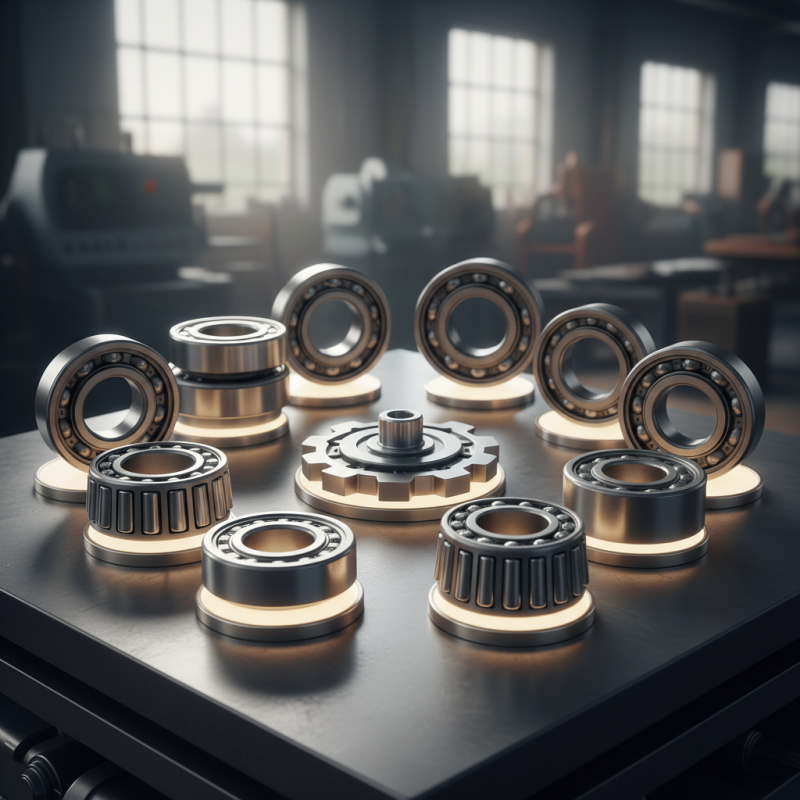

Top 10 Ball Bearing Types You Need to Know?

In the world of machinery and equipment, Ball Bearings play a crucial role. According to David Anderson, a leading expert in the ball bearing industry, "Understanding different types of ball bearings is essential for optimal performance." This statement highlights the significance of choosing the right type for various applications.

Ball bearings reduce friction and improve efficiency. However, not every type fits every use. In fact, common mistakes occur when selecting bearings. Engineers often overlook factors like load capacity and alignment. These oversights can lead to increased wear and tear on machines. Every application demands attention to detail.

As we explore the top ten types of ball bearings, it’s clear there is much to consider. Each type has distinct characteristics, benefits, and potential drawbacks. For example, deep groove ball bearings are widely used but may not be ideal for all scenarios. Careful consideration ensures better performance and longevity in machinery.

Types of Ball Bearings: An Overview of Common Variants

When exploring the world of ball bearings, it's essential to understand the various types available. Deep groove ball bearings are the most common. They support radial and axial loads effectively. Their versatility makes them suitable for different applications, from electric motors to household appliances.

Angular contact bearings are another important variant. They handle higher speeds and can manage both radial and axial loads simultaneously. These bearings come in different contact angles. Choosing the right angle can influence performance significantly.

Tip: Always consider the load requirements of your application. Selecting the wrong type could lead to failures or inefficiency.

Self-aligning ball bearings are worth mentioning too. They can accommodate shaft misalignment, which is valuable in variable load situations. This flexibility provides operational stability in less-than-perfect conditions.

Tip: Regular maintenance can prolong bearing life. Inspect them periodically for signs of wear or damage.

In summary, understanding the nuances between ball bearing types can enhance equipment performance. Knowing when and how to use each type is crucial for success.

Deep Groove Ball Bearings: Versatility in Motion

Deep groove ball bearings are essential in many applications. Their design allows them to handle both radial and axial loads. This versatility makes them a popular choice in various industries. They offer smooth rotation and reduced friction. The simplicity of their structure contributes to their reliability.

These bearings are found in everyday devices. From electric motors to bicycles, their presence is everywhere. However, their performance can be impacted by improper installation or maintenance. Users often overlook the importance of choosing the right size. Even small errors can lead to early failure.

The effectiveness of deep groove ball bearings relies on precise engineering. The internal geometry plays a critical role in load distribution. Sometimes, people forget that lubrication is equally important. A well-lubricated bearing can last significantly longer. Awareness of these factors ensures better performance in the long run. Balancing quality and cost can be tricky, but it’s crucial for optimal function.

Top 10 Ball Bearing Types You Need to Know

| Bearing Type | Load Capacity (lbs) | Speed Rating (RPM) | Temperature Range (°C) | Application |

|---|---|---|---|---|

| Deep Groove Ball Bearing | 5000 | 12000 | -20 to 100 | General Purpose |

| Angular Contact Ball Bearing | 4000 | 20000 | -30 to 120 | Machine Tool Spindles |

| Self-Aligning Ball Bearing | 3500 | 15000 | -20 to 80 | Agricultural Equipment |

| Thrust Ball Bearing | 1000 | 8000 | -20 to 60 | Vertical Applications |

| Spherical Roller Bearing | 8000 | 10000 | -30 to 120 | Heavy Machinery |

| Tapered Roller Bearing | 6000 | 9000 | -20 to 130 | Automotive Axles |

| Needle Roller Bearing | 3000 | 16000 | -20 to 100 | Compact Applications |

| Ceramic Ball Bearing | 4500 | 20000 | -40 to 120 | High-Speed Applications |

| Magnetic Bearing | N/A | 30000 | -20 to 150 | High Performance Drives |

| Fluid Film Bearing | 7000 | 5000 | -30 to 80 | Heavy Machinery |

Angular Contact Ball Bearings: Precision for High Loads

Angular Contact Ball Bearings (ACBB) are crucial in many high-load applications. Their design allows them to handle both radial and axial loads simultaneously. This unique capability makes them ideal for areas involving high-speed machinery, such as turbines and motors. According to industry studies, ACBB can increase machine lifespan by 15% when properly implemented.

When choosing ACBBs, consider their angular contact angle. A larger angle allows for greater axial load capacity but may reduce radial load handling. This trade-off can be critical in applications with mixed loads. Be aware that inadequate selection might lead to premature failure.

Tips: Regularly inspect bearing conditions. Monitor lubrication levels to prevent overheating. Ensure alignment is correct to avoid uneven wear. Adjusting operational environments can significantly extend bearing life. Make adjustments based on machine performance feedback.

Precision in selection matters. Many engineers overlook these factors. Small mistakes can lead to inefficiencies. Take time to analyze load requirements thoroughly. The right ACBB choice can make a significant difference in performance and durability.

Self-Aligning Ball Bearings: Handling Misalignments Effortlessly

Self-aligning ball bearings offer a simple yet effective solution for managing misalignments in various machinery. These bearings are designed with a special structure that allows them to adjust and adapt to misalignment caused by installation errors or operational stresses. Their unique spherical outer surface supports rotation in multiple directions, helping to minimize wear and prolong the life of the components.

In practical applications, these bearings are crucial in environments where precise alignment is challenging. Consider a conveyor system that experiences shifting loads; self-aligning ball bearings ensure smoother operation under these conditions. However, even the best designs are not immune to failure. Factors like dirt ingress or inadequate lubrication can still cause issues. Proper maintenance and regular inspections are essential to address potential problems.

Real-world scenarios show that relying solely on self-aligning ball bearings can lead to overlooked maintenance needs. For instance, a manufacturing unit might overlook routine checks, thinking that these bearings will solve all alignment issues. This mindset can lead to unexpected breakdowns, disrupting production lines. Regular attention to these components is necessary to keep them functioning effectively.

Thrust Ball Bearings: Essential for Axial Load Applications

Thrust ball bearings are crucial for applications involving axial loads. They can support heavy radial loads, but they excel in handling axial forces. These bearings consist of two raceways and a ball assembly. They are designed for rotation at low to moderate speeds. While they work well in many scenarios, they do have limitations.

Incorporating thrust ball bearings into designs can improve efficiency. They are often used in automotive and machine tools. However, improper installation can lead to failure. It's important to ensure correct alignment. Many users overlook this detail, leading to performance issues.

Another aspect to consider is lubrication. Using the right grease or oil enhances the bearing's life. However, over-lubrication can cause problems too. Finding a balance is essential. Regular maintenance can prevent unexpected breakdowns. Thrust ball bearings are indispensable but must be used with care.

Top 10 Ball Bearing Types You Need to Know

This bar chart illustrates the load capacities of different types of ball bearings, which are essential for various applications in machinery and equipment.