What is an Overflow Valve Block and How Does It Work?

The Overflow Valve Block is a critical component in hydraulic systems. It ensures pressure regulation and prevents potential damage. According to a recent industry report from the Fluid Power Society, the demand for efficient overflow systems has grown by 15% over the past five years. This highlights the importance of understanding how these systems function.

Expert Mark Thompson, a senior engineer at Hydraulics Innovations, emphasizes, "Efficiency in overflow systems is essential for safety and performance." His insights reflect the industry's rising standard for reliable components. Yet, there remains a gap in knowledge surrounding the operation of these valve blocks.

Many engineering teams are unaware of specific designs that enhance functionality. This lack of awareness can lead to inefficient systems that may not meet required safety standards. Understanding the Overflow Valve Block's workings can bridge this knowledge gap and help improve overall hydraulic performance. As systems evolve, continuous learning and adaptation remain vital.

What is an Overflow Valve Block? Definition and Importance in Fluid Systems

An overflow valve block is essential in fluid systems. It regulates pressure and helps maintain safety. This component allows fluid to bypass the main pathway when pressure exceeds a certain limit. By doing this, it prevents damage to other parts of the system. Proper function is crucial—failure could lead to leaks or system breakdown.

Tips: Regular maintenance is key. Check for signs of wear or corrosion. Ignoring small issues can lead to bigger problems later.

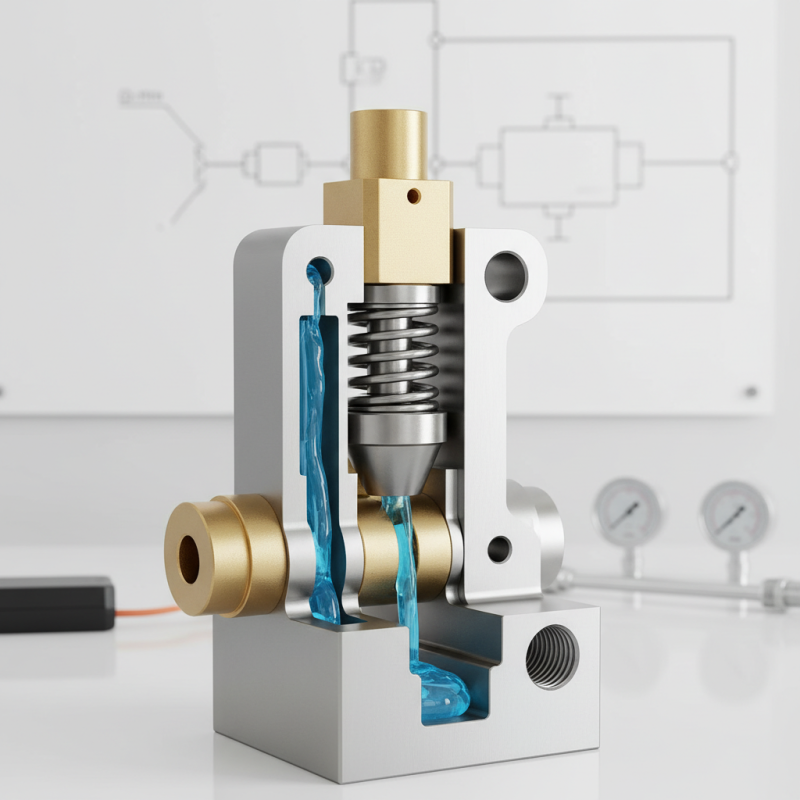

Understanding how an overflow valve block works is important. It uses a spring-loaded mechanism. When pressure builds, the valve opens, releasing excess fluid. This process ensures efficient operation and safety. However, if adjustments are not made, the block may malfunction.

Tips: Always consult a professional for complex issues. Incorrect adjustments can result in system inefficiencies. Awareness of your system’s behavior helps in timely interventions.

Key Components of an Overflow Valve Block and Their Functions

An overflow valve block is crucial in fluid power systems. It regulates pressure and prevents damage from over-pressurization. The key components include the valve body, spring, and actuator. The valve body houses the internal mechanisms. It plays a significant role in directing fluid flow.

The spring provides the necessary force to keep the valve closed under normal operating pressures. When pressure exceeds a set limit, the spring compresses, allowing fluid to escape. This action prevents system components from being exposed to potentially damaging levels. An industry report revealed that improper management of overflow systems can lead to failures costing companies millions.

Another important element is the actuator, which is responsible for controlling the valve’s opening and closing. Actuators can be pneumatic or hydraulic, influencing response times. Many designs fail to account for wear and tear on these components, leading to inefficiencies. Regular maintenance checks are critical. Ignoring these can sum up to a significant risk over time.

Mechanism of Operation: How an Overflow Valve Block Regulates Pressure

An overflow valve block plays a crucial role in fluid systems. Its primary function is to regulate excess pressure. This helps prevent system failures and ensures safe operations. According to industry reports, improper pressure regulation can lead to costly downtimes—estimated at up to 30% of operational costs.

The mechanism of operation is quite fascinating. When the pressure exceeds a preset limit, the overflow valve opens. This allows excess fluid to bypass critical areas, preventing damage. In hydraulic systems, for example, maintaining a pressure range is vital. A report from the Hydraulic Institute notes that even minor deviations can result in efficiency losses of 15% or more. Thus, overflow valve blocks serve as a safety net against such inefficiencies.

Understanding the dynamics of these devices isn’t always straightforward. Incorrect settings can lead to constant cycling, which wastes energy. Engineers must carefully tune systems to avoid these pitfalls. The response time of the valve can greatly impact system performance. For instance, a slow response can cause pressure spikes that may compromise system integrity. Monitoring this aspect is essential for maintaining optimal function.

Applications of Overflow Valve Blocks in Industrial Hydraulics

Overflow valve blocks play a crucial role in industrial hydraulics. They manage excess fluid in hydraulic systems, ensuring safety and efficiency. These blocks prevent overpressure by redirecting fluid. In a hydraulic system, maintaining correct pressure is vital. Research shows that improper pressure control can lead to system failures and costly repairs.

In various applications, overflow valve blocks serve distinct purposes. They are prominent in machinery such as excavators and forklifts. A study indicates that hydraulic systems that include overflow valve blocks experience a 25% reduction in operational failures. These blocks help maintain consistent pressure, enhancing performance. They allow hydraulic fluid to flow back to the reservoir, avoiding pressure spikes.

However, not all systems effectively use these blocks. Over time, wear and tear can compromise their functionality. Regular maintenance is essential but often overlooked. Ignoring this can lead to inefficiencies and increased costs. Businesses must reflect on their hydraulic systems' maintenance practices. Optimizing these practices can lead to better performance and reliability in operations.

Performance Metrics: Efficiency and Reliability of Overflow Valve Blocks

Overflow valve blocks are essential in hydraulic systems. They help maintain pressure and prevent damage. Efficiency is a key performance metric. A well-functioning valve block minimizes energy loss. This ensures systems operate smoothly, saving costs in the long run.

Reliability is another critical factor. A faulty valve can lead to system failures. Regular maintenance is necessary to enhance performance. Users often overlook this aspect. They might assume that if it works, it will always work. However, wear and tear can impact efficiency over time.

Evaluating performance metrics requires careful monitoring. Simple tests can help assess flow rates and pressure levels. Users should be aware of potential issues. They should not ignore warning signs. Being proactive can prevent costly downtime and extend the lifespan of hydraulic systems.

Performance Metrics of Overflow Valve Blocks

This chart illustrates the performance metrics of overflow valve blocks, demonstrating their efficiency, reliability, response time, and pressure range. High values in efficiency and reliability indicate a robust performance, while lower response time and appropriate pressure range are critical for operational effectiveness.