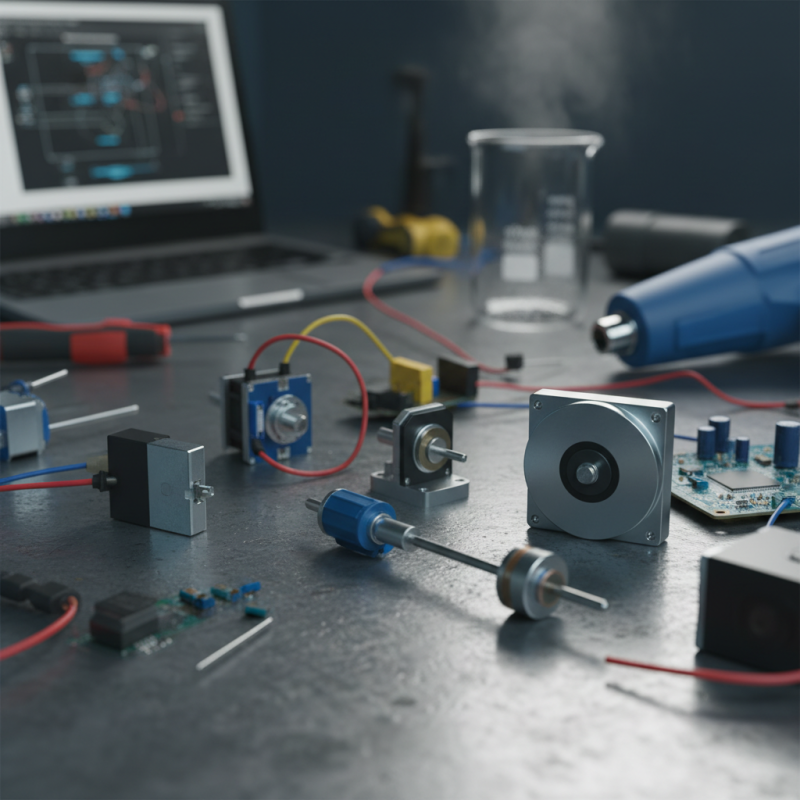

How to Choose the Right Position Sensor for Your Project?

Choosing the right Position Sensor for your project can be challenging. There are many options available, each with unique features. Understanding your specific needs is essential.

Position Sensors play a crucial role in various applications. They can measure rotation, linear displacement, or angular position. Selecting the wrong sensor can lead to significant issues. You might face accuracy problems or compatibility challenges.

Consider the environment where the sensor will operate. Will it be exposed to heat or moisture? This information impacts your choice. Look for sensors that can endure such conditions. Additionally, evaluate the sensor's output type and resolution. You want reliable and precise data for your project.

Understanding the Basics of Position Sensors

Position sensors are essential components in various projects. They help detect the position of an object accurately. Understanding the basics of these sensors is crucial before selecting one for your project. There are different types, such as potentiometric, magnetic, and optical sensors. Each has its unique features and applications. For example, potentiometric sensors can provide precise measurements, while magnetic sensors are known for their robustness.

When choosing a position sensor, consider the environment. Temperature, humidity, and potential interference can impact performance. For instance, optical sensors may struggle in dusty environments. In contrast, magnetic sensors perform well under harsh conditions. Additionally, reflect on the required accuracy. Will your project need high precision, or is a general approximation sufficient? This contemplation can guide your decision.

Many people overlook the importance of signal output. Some sensors provide analog signals, while others offer digital outputs. Understanding these differences is vital for your project's needs. Additionally, installation and maintenance can also pose challenges. Assessing how easy it is to integrate the sensor into your system can save time. Many users often find themselves regretting not considering this aspect earlier.

Types of Position Sensors and Their Applications

Position sensors play a crucial role in various applications. They help determine the position of an object accurately. Different types of position sensors exist, each with unique features and benefits. Common types include potentiometers, encoders, and linear variable differential transformers (LVDTs).

Potentiometers are simple, cost-effective sensors. They provide continuous position feedback through resistance changes. They work well in applications such as robotics or automotive controls. Encoders, on the other hand, offer better precision. They can be incremental or absolute. These sensors are widely used in industrial automation, providing reliable data for controlling machinery.

When selecting a position sensor, consider your project’s requirements. Think about accuracy, range, and environmental conditions. Ask yourself: What’s the expected range of motion? Will it operate in harsh conditions?

Tip: Assess the installation space. Some sensors may require specific mounting, which could complicate your design. Be mindful of power supply needs. Ensure compatibility with your existing setup for optimal performance. Always test your sensor in a controlled environment before full deployment. There could be unexpected challenges. Consider revisiting your choices if issues arise.

Key Factors to Consider When Selecting a Position Sensor

Choosing the right position sensor is crucial for any project. It can significantly affect the performance and accuracy of the system. Start by considering the application requirements. Do you need precision or is general accuracy sufficient? High precision sensors often come with a higher cost. Keep budget constraints in mind while balancing performance metrics.

Next, examine the environmental conditions where the sensor will operate. Factors like temperature, humidity, and exposure to dust or chemicals matter. A sensor that works well in a lab may fail outdoors. Think about the installation space as well. Larger sensors might not fit in compact designs. Evaluate how easy it is to install and integrate the sensor into your existing system.

Lastly, consider the output type. Some sensors provide analog signals, while others offer digital. Understand what your system requires. You may need to rethink your decision if the output does not match your requirements. Ultimately, careful evaluation and understanding of these factors will lead to a better choice of position sensor for your project.

Evaluating Accuracy and Resolution Requirements

When selecting a position sensor, accuracy and resolution are key factors. Accuracy refers to how close a sensor's measurement is to the true position. For some projects, a small error is acceptable. For others, even a tiny discrepancy can lead to significant issues. You might need to test several sensors to find one that meets your specific needs.

Resolution determines the smallest change in position a sensor can detect. A higher resolution means finer detail. This is crucial for applications like robotics or precision CNC machines. However, higher resolution sensors often come at a higher cost and may complicate your design. Balancing cost and performance can be challenging. Sometimes, it's tempting to opt for the highest specifications, but this might not always be necessary.

Consider real-world scenarios. If you’re measuring linear motion in a small robotics project, a sensor with moderate accuracy might suffice. Yet, if you're developing aerospace applications, every detail matters. In such cases, investing in a precise sensor could be worth it. Experiment with different sensors and collect data. Reflect on your project requirements and adjust as necessary. The best choice may not be clear at first.

Integration and Compatibility with Existing Systems

When selecting a position sensor, integration with existing systems is crucial. Check if the sensor can easily fit into your current setup. Not all sensors work seamlessly with every system. Understanding your system's specifications is the first step. Interfaces may vary, so be wary of compatibility issues. A mismatched sensor can lead to frustrating data discrepancies.

Consider communication protocols as well. Some sensors use digital signals while others might rely on analog outputs. Ensure that your data processing units can interpret the sensor's signal type. This can limit your choices significantly. It’s essential to evaluate the technology stack in your project.

Don't overlook the power requirements too. Different sensors may consume varying amounts of energy. This could impact your project’s design and efficiency. Sometimes, it's easy to assume low power consumption is a given. However, this isn't always the case. A sensor that does not align with your power needs can complicate your project. Every detail matters when striving for optimal performance.