Why Choose a Damper Actuator for Your HVAC System?

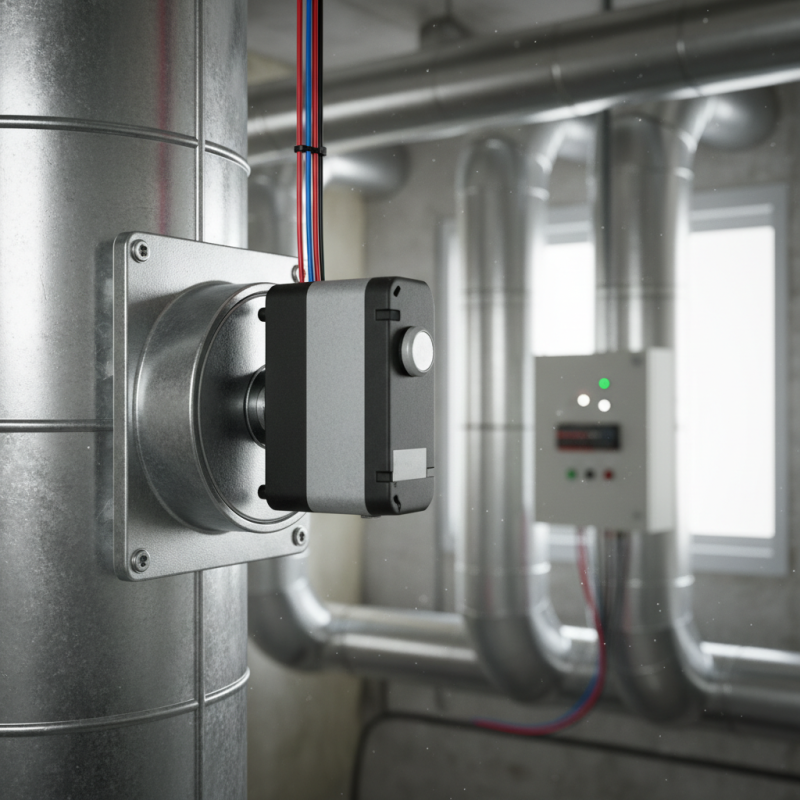

In today’s evolving HVAC landscape, the importance of a reliable Damper Actuator cannot be overstated. These devices play a crucial role in regulating airflow and maintaining indoor air quality. A properly functioning damper actuator ensures that air distribution is both efficient and consistent, which directly impacts energy consumption.

Without a damper actuator, HVAC systems can struggle. They might face airflow imbalances, leading to discomfort. Many systems fail to utilize this vital component, often neglecting its benefits. This oversight can result in unnecessary energy waste and higher utility bills. Consider the comfort of a room; uneven temperatures can be frustrating.

The choice of a high-quality damper actuator can transform an HVAC system’s performance. However, selecting the right one is vital. Factors such as size, compatibility, and control options need thorough consideration. A thoughtful approach will reveal the essential role that a damper actuator plays in achieving optimal HVAC efficiency.

The Importance of Damper Actuators in HVAC Efficiency

Damper actuators play a crucial role in HVAC efficiency. They control the airflow in heating, ventilation, and air conditioning systems. By adjusting dampers, these devices ensure optimal air distribution. Good airflow reduces energy waste and enhances comfort. Without effective damper actuators, HVAC systems can become inefficient.

Consider a scenario where dampers remain partially closed. The system works harder to compensate. This increases energy consumption. A well-functioning actuator can prevent such issues. It keeps the airflow balanced. This improves both energy efficiency and indoor air quality.

Tip: Regularly check your damper actuators. Dust and grime can affect their performance. Keeping them clean ensures smooth operation.

Incorporating damper actuators offers more than just airflow control. They help in maintaining temperature consistency. However, improper installation can lead to poor results. Ensure that they are correctly calibrated for your specific system to avoid problems down the line.

Tip: Consult a professional for proper installation. They can also provide guidance on maintenance routines. This will prolong the life of your HVAC system.

Understanding the Role of Damper Actuators in Airflow Management

Damper actuators play a critical role in managing airflow within HVAC systems. These devices control dampers, which regulate the amount of air traveling through ducts. When installed correctly, they enhance energy efficiency. A recent report indicated that proper airflow management could lead to energy savings of up to 30% in commercial buildings. This highlights the importance of investing in quality damper actuators.

Understanding the mechanics of damper actuators is essential. They can be electric, pneumatic, or hydraulic. Each type has unique advantages and specific applications. However, selecting the wrong actuator can lead to inefficient airflow. For instance, an actuator that is too weak may struggle to fully open or close a damper, reducing system performance. According to industry statistics, poorly functioning airflow systems can increase energy consumption by 15% or more.

Regular maintenance of damper actuators also cannot be overlooked. Wear and tear can affect their responsiveness. Ignoring these issues can result in considerable energy loss over time. Many facility managers underestimate the impact of a malfunctioning actuator. This can lead to missed opportunities for improved comfort and efficiency. In the long run, investing in robust damper actuators and their upkeep is vital for effective airflow management.

Why Choose a Damper Actuator for Your HVAC System?

| Dimension | Description | Importance |

|---|---|---|

| Response Time | The speed at which the damper actuator responds to control signals. | Crucial for maintaining precise airflow and temperature control. |

| Torque Rating | The maximum torque that the actuator can exert to open or close the damper. | Ensures the actuator can operate larger dampers effectively. |

| Control Type | The type of control mechanism (e.g., direct or modulating). | Determines the flexibility in controlling airflow density. |

| Power Supply | The required voltage and current for operation. | Impacts installation and compatibility with the HVAC system. |

| Feedback Mechanism | The method for providing position feedback to the control system. | Enhances system accuracy and energy efficiency. |

Comparative Analysis: Manual vs. Automated Damper Actuators

When considering dampers for HVAC systems, the choice between manual and automated actuators is crucial. Manual actuators require human intervention to operate the dampers. This can lead to delays and inefficiencies, especially in larger systems. For instance, a technician may need to climb into a ceiling space to adjust a damper. This not only consumes time but also disrupts system performance.

On the other hand, automated damper actuators offer improved efficiency. They allow real-time adjustments based on system demands. Automated systems can respond to changing temperatures or occupancy levels quickly. However, they can be more complex to install and require regular maintenance. Some users might find them overwhelming or prone to malfunction.

Choosing between manual and automated options involves trade-offs. Manual actuators may be simpler and less costly upfront. Yet, they lack the responsiveness of automation. Automated systems can optimize air flow dynamically but also pose a higher risk of technical failures. Ultimately, the decision depends on specific needs and the scale of the HVAC system in use.

Key Features and Benefits of Modern Damper Actuators

When considering modern HVAC systems, damper actuators stand out for their key features and benefits. These devices regulate airflow effectively, which contributes to energy efficiency. They help maintain consistent temperatures across different areas. A well-regulated flow can improve indoor air quality significantly.

One notable feature of damper actuators is their precision control. This ensures that the right amount of air reaches each space. Inadequate airflow can lead to discomfort or inefficient heating and cooling. Additionally, many modern actuators come with advanced automation capabilities. This allows them to respond in real-time, adjusting based on the needs of the environment.

Reliability is another critical aspect. However, not all actuators perform equally well. Some may have delay issues or insufficient range. It’s important to choose actuators that fit specific system requirements. Maintenance is also vital; without it, performance can decline over time. Evaluating these factors can lead to better long-term results for HVAC systems.

Features and Benefits of Modern Damper Actuators in HVAC Systems

This chart illustrates the key features and their importance levels of modern damper actuators in HVAC systems. Precision control and response time are critical factors, while features like durability and installation ease also play significant roles in the overall efficiency and reliability of HVAC operations.

Impact of Damper Actuators on Energy Consumption and Cost Savings

Damper actuators play a crucial role in optimizing HVAC systems. They regulate airflow frequency and maintain proper pressure. According to a report by the U.S. Department of Energy, implementing these devices can reduce energy consumption by up to 30%. This significant reduction translates to lower utility costs. Yet, many facilities still overlook their importance.

The financial benefits are compelling. A well-designed system can lead to annual savings of $2,000 to $10,000. However, not all installations maximize their potential efficiency. Regular maintenance of damper actuators is often neglected. This lack of attention can diminish performance over time and increase energy costs. Proper inspection ensures they function optimally.

While many HVAC systems incorporate dampers, the integration of actuators is sometimes incomplete. This oversight can hinder a building's energy performance. Facilities should assess their systems critically. Upgrading or maintaining actuators may require upfront costs, but the long-term savings can be substantial. Investing in these components can generate measurable benefits for both the environment and the bottom line.