Why Choose an Alloy Powder Grader for Your Manufacturing Needs?

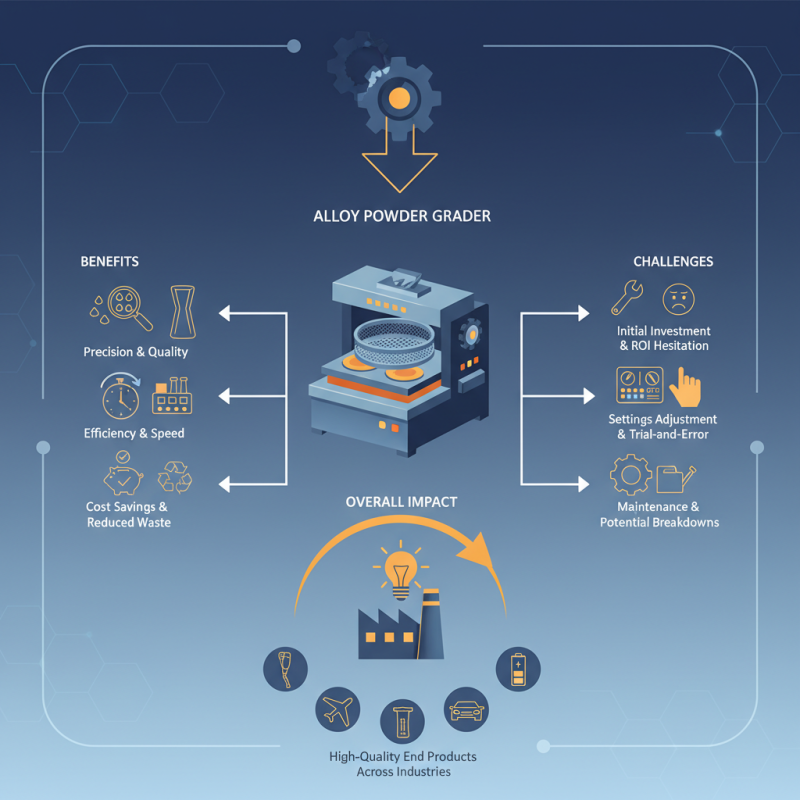

In today's manufacturing landscape, precision matters more than ever. An Alloy Powder Grader plays a pivotal role in ensuring that metal powders are graded accurately and uniformly. These machines enhance efficiency, directly impacting product quality. Moreover, they can save costs by reducing waste in the production process.

However, not all manufacturers recognize the value of an Alloy Powder Grader. There can be hesitation due to initial investment concerns. Some may wonder about the actual return on investment. It's crucial to assess how these graders can affect overall productivity. Many industries rely on high-quality powders for their end products.

The use of an Alloy Powder Grader may also lead to challenges. Adjusting the settings for different materials might require trial and error. Moreover, proper maintenance is key to avoiding breakdowns. Despite these potential drawbacks, the advantages often outweigh the challenges. This makes understanding Alloy Powder Graders essential for any serious manufacturer.

Benefits of Using Alloy Powder Graders in Manufacturing Processes

Choosing an alloy powder grader can significantly enhance your manufacturing processes. These machines ensure consistency in particle size, which is crucial for quality. A uniform particle size leads to better mixing and improved mechanical properties in the final product. Additionally, greater accuracy reduces material waste, saving both time and money.

Tips: Regular maintenance of your alloy powder grader is essential. Ensure it is calibrated frequently to maintain accuracy. Monitor the powder flow to avoid clogs, which can disrupt production.

Utilizing alloy powder graders also contributes to a healthier working environment. Enhanced particle distribution leads to fewer airborne particles. This reduces the risk of respiratory issues among workers. However, it's important to note that high-quality materials and proper training are still necessary. Sometimes even the best machines can fail if not used correctly.

Consider the layout of your manufacturing space. An efficient design can make it easier to operate your grader and keep processes streamlined. Small changes can lead to significant improvements in productivity over time.

Key Features to Look for in Alloy Powder Grading Equipment

Choosing the right alloy powder grading equipment is critical for manufacturing. One key feature to consider is accuracy. Graders should deliver precise measurements of particle sizes. An accurate grader ensures consistent quality in the final product. Manufacturers cannot afford to overlook this element.

Another important aspect is ease of use. The best alloy powder graders have intuitive controls. This feature can save time and reduce errors during operation. Operators should feel comfortable adjusting settings quickly. Complex machines may lead to operational hiccups. Simplicity in design helps streamline the grading process.

Finally, maintenance is crucial. Equipment should be easy to clean and maintain. Regular upkeep can extend the life of the grader. However, some machines may have hard-to-reach areas. This can make cleaning a challenge, leading to frustration. Manufacturers need to weigh these factors carefully when selecting their grading equipment.

Comparative Analysis: Alloy Powder Graders vs. Traditional Grading Methods

The transition from traditional grading methods to alloy powder graders has become increasingly important in manufacturing. A recent report indicates that manufacturers face challenges with conventional techniques, such as time inefficiency and human error. These issues can lead to inconsistencies in product quality, impacting overall production rates.

Alloy powder graders offer significant advantages. Their precision in sorting and classifying materials enhances quality control. For example, studies show that using advanced grading technology can reduce sorting errors by up to 50%. This improvement is crucial for industries that require high-grade materials, such as aerospace and medical devices. Meanwhile, traditional methods often result in wasted resources due to misclassifications.

However, the shift towards alloy powder graders is not without challenges. Some manufacturers may find the initial investment daunting. Training staff to operate new machinery requires time and effort. Yet, the long-term benefits, such as reduced waste and improved accuracy, often outweigh these concerns. The need for adaptation is critical in today’s competitive landscape. Balancing cost and efficiency remains a pressing issue for many businesses.

Impact of Alloy Powder Grading on Product Quality and Consistency

Alloy powder grading significantly affects the overall quality and consistency of manufactured products. According to a recent report by the International Journal of Advanced Manufacturing Technology, inconsistency in particle size can lead to substantial defects in final products. For example, when particle sizes vary by more than 10%, the density and flowability of the powder change. This results in poor mixing, which directly impacts the mechanical properties of the finished component.

Different industries demand specific alloy powder grades to achieve optimal results. The aerospace sector, for instance, requires precise grading for quality assurance. A study by the Materials Science and Engineering journal highlights that graded powders enhance uniformity, leading to 30% stronger components. The correlation between grading precision and performance metrics is undeniable. Nevertheless, many manufacturers overlook the potential of proper grading. This oversight can lead to expensive reworks and delayed production schedules.

While there is a clear link between grading and product performance, achieving perfect grading remains a challenge. Variability in supply and production processes adds complexity. Many manufacturers struggle to maintain consistency across batches. Improving the grading process is an ongoing task. Addressing these issues can yield significant benefits, ultimately enhancing overall operational efficiency.

Cost Efficiency and ROI: Investing in Alloy Powder Grading Technology

Alloy powder grading technology can enhance manufacturing efficiency. It offers cost-effective solutions for producers. Investing in this technology brings a solid return on investment (ROI). This is vital in competitive markets where margins are tight.

When manufacturers use an alloy powder grader, they improve product consistency. This leads to fewer defects and waste. Reducing waste directly impacts costs and boosts profitability. However, it’s essential to consider initial setup costs. Sometimes, that can deter potential buyers. Think about the long-term savings. Those can outweigh upfront expenses.

**Tip:** Regularly evaluate your grading system. Look for areas of improvement. Small adjustments can result in significant gains.

Employing alloy powder grading can streamline operations. It enhances the workflow and reduces time in production. Yet, companies should not overlook employee training. Without proper guidance, the technology may underperform.

**Tip:** Conduct training sessions to maximize efficiency. A well-trained workforce is crucial for technology success.

Why Choose an Alloy Powder Grader for Your Manufacturing Needs? - Cost Efficiency and ROI: Investing in Alloy Powder Grading Technology

| Feature | Description | Cost Impact (%) | ROI (Return on Investment) |

|---|---|---|---|

| Increased Material Quality | Enhanced particle size distribution for better performance | 15% | 20% |

| Process Efficiency | Streamlined manufacturing processes | 10% | 25% |

| Waste Reduction | Minimized scrap and rework | 20% | 30% |

| Labor Savings | Reduced manual handling and better automation | 5% | 15% |

| Long-Term Durability | Investing in technology that lasts | 8% | 18% |