Center Bearing Essential Tips for Optimal Performance?

In the world of automotive engineering, the Center Bearing plays a pivotal role in propelling vehicle performance. Expert Tom Richards emphasizes, "A well-maintained Center Bearing can prevent costly repairs." This highlights the importance of proper care for this often-overlooked component.

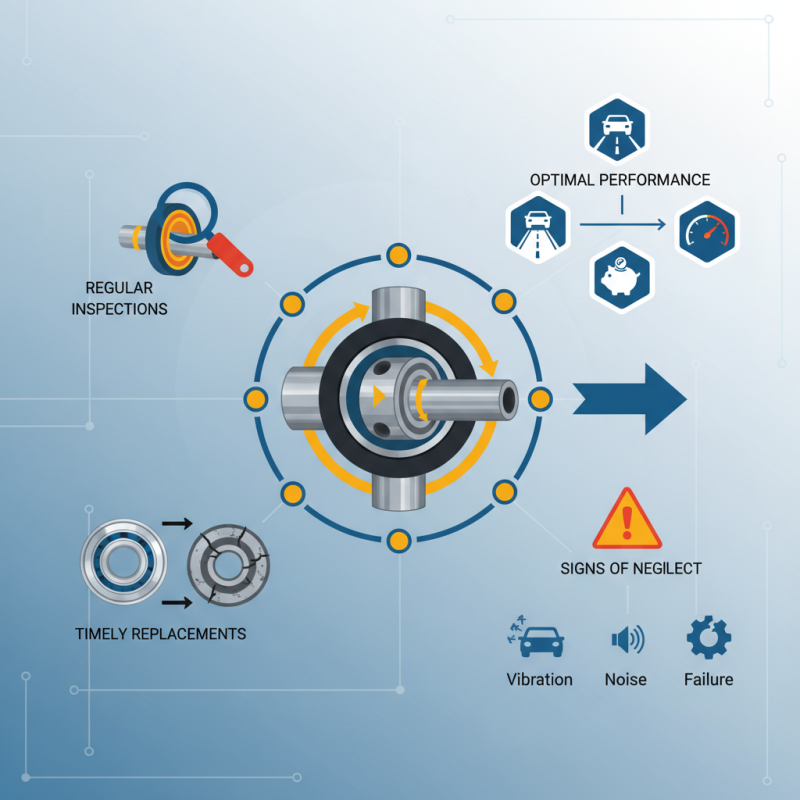

Center Bearings are crucial for ensuring smooth operation of driveshafts. Neglecting their maintenance can lead to vibration, noise, and even complete failure. Regular inspections and timely replacements can greatly enhance a vehicle's longevity. However, many vehicle owners are unaware of this critical aspect.

Understanding the specific requirements for Center Bearing care is essential. Drivers must remain vigilant of signs signaling potential issues. Ignoring these can result in a cascade of mechanical failures. A proactive approach toward Center Bearings not only protects vehicles but also improves overall performance on the road.

Center Bearing Overview: Definition and Functionality Explained

Center bearings are critical components in many mechanical systems. They support rotating shafts aligned with drive trains. Without them, vibrations and misalignments may occur, leading to system failure. Properly functioning center bearings ensure fluid motion and stability.

Understanding how center bearings work is essential. They typically consist of a shaft encased in a housing with bearings. This design allows them to reduce friction and handle axial loads. However, if they are not maintained, they can develop issues. Noise or excess play can indicate wear or damage. Regular inspections can help prevent these problems, but many overlook this.

The placement of center bearings plays a significant role in their performance. They should be strategically positioned along the shaft for optimal load distribution. Misalignment can lead to premature wear. Additionally, consider the environment where they operate. Dust and moisture can severely impact their lifespan. A simple clean-up can be beneficial.

Key Factors Influencing Center Bearing Performance in Vehicles

Center bearings play a crucial role in vehicle performance. They support the driveshaft and help to maintain its alignment. Several key factors influence the performance of center bearings in vehicles. According to industry reports, improper installation can lead to excessive vibrations, wear, and eventual failure.

One major factor is load capacity. A center bearing must bear varying loads during operation. It is essential to ensure that the bearing is rated correctly for specific applications. Overloading can reduce its lifespan significantly. Regular inspections can identify issues before they escalate.

Tip: Monitor for unusual noises or vibrations. Early detection can save costs and enhance safety.

Another element is lubrication. Proper lubrication minimizes friction and prevents overheating. According to a study from the Automotive Engineering Institute, lack of lubrication can increase wear rates by up to 50%. Additionally, environmental factors like temperature and moisture can affect lubrication efficiency.

Tip: Regularly check lubricants and replace them as needed. This simple act can double bearing longevity.

Remember, even high-quality bearings can fail if neglected. Consider your vehicle's operating conditions and maintenance schedule. Being proactive protects against costly repairs and downtimes.

Common Issues with Center Bearings and Their Impact on Durability

Center bearings play a crucial role in vehicle performance. Common issues arise from improper installation, wear, and exposure to environmental factors. These problems can significantly impact the durability of not only the center bearing but also other connected components.

Vibrations are a common sign of issues with the center bearing. They can lead to quicker deterioration. Misalignment is another concern. It can cause uneven wear and shorten lifespan. Regular inspections can help identify these issues early. Ensuring proper lubrication is vital, yet many neglect this aspect.

Ignoring wear and tear can lead to serious damage. It's essential to pay attention to noises and vibrations. Over time, a worn center bearing can affect the entire drive train. Investing time in maintenance is often overlooked. Many wish they had paid more attention to these details earlier. Taking proactive steps can save time and money in the long run.

Maintenance Strategies for Extending Center Bearing Lifespan

Center bearings play a crucial role in the performance of various machinery. Proper maintenance is essential to prolong their lifespan. A recent industry report indicates that 30% of center bearing failures stem from inadequate lubrication. Regularly checking and replacing lubrication can help prevent wear and tear.

Vibration is another significant factor affecting center bearings. Studies have shown that maintaining alignment reduces the risk of vibrations. Misalignments can lead to premature failure. Keeping equipment aligned and regularly inspecting for signs of wear can enhance performance.

Moisture and contamination pose risks, too. Approximately 25% of bearings fail due to environmental factors. Using protective covers can minimize exposure to harsh conditions. A proactive approach to maintenance addresses these concerns and encourages longevity. However, it's vital to recognize that even with the best strategies, unforeseen issues can arise.

Center Bearing Essential Tips for Optimal Performance

| Maintenance Tip | Frequency | Benefits | Common Issues Prevented |

|---|---|---|---|

| Regular lubrication | Every 500 miles | Reduces friction, improves efficiency | Wear and overheating |

| Visual inspection | Monthly | Identifies damage early | Cracks and misalignment |

| Tightening bolts | Every 1000 miles | Ensures stability | Vibrations and noise |

| Cleaning bearing surface | Every 3000 miles | Prevents dirt accumulation | Decreased performance |

| Replacing worn bearings | As needed | Restores functionality | Failure and malfunction |

Industry Standards: Comparing Center Bearings Across Different Manufacturers

When it comes to center bearings, industry standards can differ significantly among various manufacturers. Understanding these differences is crucial for selecting the best option for your needs. According to a recent report by the Mechanical Engineering Journal, the dimensional accuracy and material quality of center bearings can vary by as much as 25% between competing brands. This discrepancy can affect performance, longevity, and overall reliability.

One key consideration is load capacity. Some manufacturers report higher load-bearing capacities, yet real-world tests highlight inconsistencies. A study by Bearing Technologies found that more than 35% of users experienced early failures due to overlooked specifications. It's imperative to check the manufacturer's guidelines closely and ensure they align with your application’s requirements.

Tips:

- Always conduct thorough research before making a choice.

- Verify the specifications and compare performance results.

- Engage with industry professionals to gain firsthand insights.

- Invest in quality over price to avoid hidden costs down the line.

- Remember, your decision impacts long-term performance.